At its core, a dynamometer is a device designed to measure force. It operates by applying a controlled resistance against a moving object and then precisely recording the effort required to overcome that resistance.

Unlike a simple bathroom scale that measures static weight, a dynamometer is an advanced tool for quantifying the dynamic push, pull, or twist generated during an actual movement. It's engineered to measure the real-world energy an engine, motor, or muscle can produce.

What a Dynamometer Is and How It Measures Force

To understand how a dynamometer operates, picture it as a device that presents a specific challenge and then records the response with high precision. In fields like physiotherapy and sports conditioning, this capability is transformative. It allows practitioners to move beyond subjective assessments like "that feels strong" and into the realm of objective, repeatable data.

This shift toward quantifiable measurement is crucial for tracking rehabilitation progress or fine-tuning an athlete's performance based on evidence.

Fundamentally, a dynamometer quantifies two key components of power: torque (rotational force) and rotational speed (how fast something is spinning). By measuring these two variables, it can calculate the total power output. It’s analogous to knowing not just how hard you can press on a bicycle pedal, but also how fast you can turn the crank.

The Core Principle of Measurement

The mechanics behind this process are elegantly simple. A dynamometer applies a controllable load to a muscle or an engine and measures its torque and speed to determine power. The central concept involves converting the mechanical energy produced into another, more easily measurable form—often heat—using a specialized braking system.

In short, the device creates a quantifiable "brake." The amount of force needed to move against this brake reveals exactly how much strength is being generated in that instant.

This process provides clinicians with invaluable data. For example, a physical therapist can determine if a patient's quadriceps strength has returned to at least 90% of their uninjured leg before clearing them for sports—a common evidence-based benchmark for return-to-play decisions after injuries like an ACL reconstruction (1). Understanding the basics of what is force measurement is the first step in appreciating how this technology delivers such critical insights.

This simple yet powerful concept is the foundation for all dynamometer functions. To break it down further, here is a simple table outlining the key principles at play.

Key Principles of Dynamometer Operation

| Concept | Simple Explanation | What It Measures |

|---|---|---|

| Applied Resistance | The device creates a controlled "brake" or load. | The external force that the muscle or engine must work against. |

| Torque | The rotational or twisting force generated. | The "strength" of the push, pull, or twist around an axis. |

| Rotational Speed (RPM) | How fast the object is spinning or moving. | The velocity component of the movement. |

| Power Calculation | Combines torque and speed (Power = Torque x Speed). | The overall rate of work being done—the ultimate performance metric. |

Understanding these building blocks helps clarify how a simple test can provide such a deep look into muscular function and performance.

Exploring the Core Mechanics of a Dynamometer

To fully appreciate what makes a dynamometer work, we need to examine the principles used to create and measure resistance. At its heart, a dynamometer's function is to apply a controlled "brake" to a moving system—like a contracting muscle or a spinning engine—and measure the force needed to do so.

This entire process is rooted in a fundamental law of physics: energy conversion. The mechanical work being performed is transformed into heat. The specific method used for this energy conversion is what defines the different types of dynamometers. Let's explore two of the most common designs found in both performance and clinical settings.

The Eddy Current Dynamometer

One of the most precise designs available is the eddy current dynamometer. Imagine trying to stir a thick, magnetic fluid. The faster you attempt to stir, the more viscous the fluid seems to become, creating greater resistance. This serves as a useful analogy for how an eddy current dynamometer works, but without any physical fluid or contact.

This design utilizes a rotating metal disc (the rotor) that spins within a powerful magnetic field. As the rotor moves, it induces small, circular electrical currents within the metal itself, known as eddy currents. These currents generate their own magnetic fields that oppose the main field, creating a perfectly smooth, contactless braking force. The system's elegance lies in its precision; the strength of this braking action can be adjusted with incredible accuracy simply by varying the electrical current supplied to the electromagnets.

The Water Brake Dynamometer

Another effective design is the water brake dynamometer. Consider the experience of rowing a boat. The harder and faster you pull the oar through the water, the more resistance you feel. This device operates on a similar fluid-based principle.

In these dynamometers, mechanical energy is converted into heat through fluid friction. The system functions by forcing water through the dynamometer's rotating components. As an engine or motor spins the internal parts, the water is accelerated and then rapidly decelerated within the machine's housing, which creates the resistive load. You can explore more about how this process creates a measurable load in various test and measurement applications.

Both designs—whether magnetic or hydraulic—are ultimately about creating a measurable and controllable resistance. The energy isn't lost; it's converted into heat that can be safely managed, typically with a cooling system.

Understanding this braking action is key to seeing how a dynamometer translates a raw physical effort into a precise measurement. If you wish to delve deeper into the mathematics behind this conversion, our guide on force calculation formulas may be helpful. This is the bridge that connects raw mechanical output to the actionable data that professionals depend on.

Translating Physical Force into Digital Data

While a dynamometer's mechanical braking system excels at creating resistance, the conversion of a real-world push or pull into a number on a screen is where the technology truly shines. This process bridges the gap between raw physical effort and precise digital data, relying on highly sensitive sensors and a data acquisition system.

At the core of most modern dynamometers is a small but critical component called a strain gauge. It can be thought of as a hyper-sensitive electronic sticker bonded to a part of the device specifically designed to flex slightly under load. When a force is applied, this structure bends, stretching or compressing the strain gauge along with it.

This microscopic change alters the gauge's electrical resistance. Although the shift is minuscule, it is directly proportional to the amount of force applied. This subtle electrical signal is the very first step in converting a physical action into a format a computer can interpret.

From Electrical Signal to Actionable Metric

A raw signal from a strain gauge is not yet usable data. A dynamometer's "nervous system"—its data acquisition system (DAQ)—is responsible for capturing, refining, and translating these signals into clear, actionable information. It acts as the interpreter between the physical and digital worlds.

The DAQ performs several key tasks:

- Signal Amplification: The initial electrical signal from the strain gauge is very faint. The DAQ boosts it to a level that can be accurately measured.

- Analog-to-Digital Conversion: It then converts the continuous analog signal into a digital format composed of discrete numerical values.

- Data Processing: Using built-in calibration factors and algorithms, it translates these digital numbers into standard units of force, such as Newtons (N) or pounds (lbs).

- Integration with Other Sensors: In more advanced systems, it also gathers data from other sensors, such as those measuring rotational speed (RPM), which is essential for calculating power.

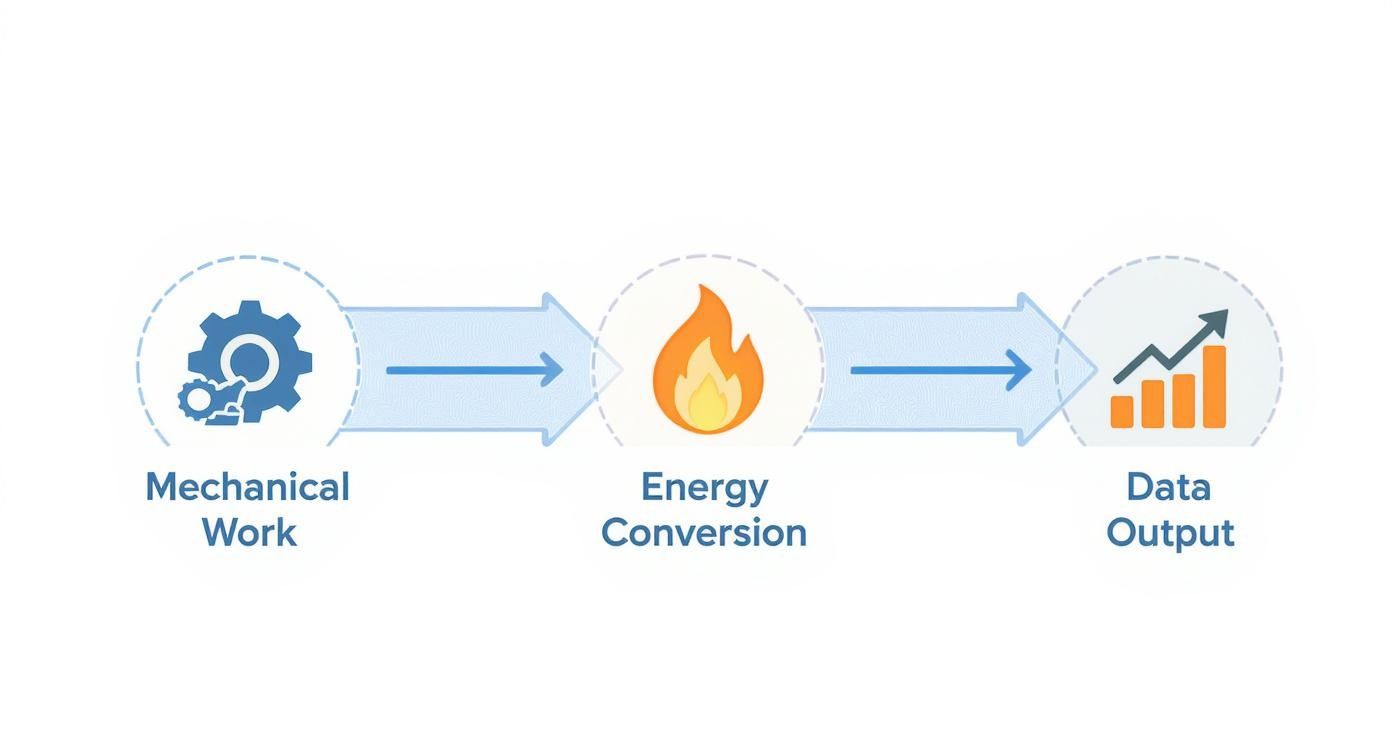

This infographic breaks down how that mechanical work gets converted into useful data.

As you can see, a dynamometer doesn’t just measure force; it manages a complete process of energy conversion and data translation from start to finish.

In simple terms, the data acquisition system captures thousands of these tiny electrical snapshots every second. This rapid sampling rate allows it to build a highly detailed picture of how force changes over time, capturing everything from the explosive peak force of a jump to the steady output during an isometric hold (1).

This entire sequence—from the physical stress on a strain gauge to the final, calculated number displayed on a screen—is how a dynamometer provides the objective data that clinicians and coaches depend on to make smarter, more informed decisions.

How Professionals Interpret Dynamometer Data

A dynamometer produces a stream of numbers, but raw data alone is of limited value. The real utility emerges when a skilled professional translates those numbers into actionable insights. Understanding how a dynamometer works is the first step; knowing what the data reveals about human movement, strength, and recovery is what truly matters. This is where abstract measurements become powerful tools for making clinical and performance decisions.

For clinicians and coaches, these numbers tell a story. They can reveal subtle weaknesses not visible to the naked eye, track recovery milestones with objective precision, and pinpoint specific areas for improvement. A dynamometer doesn't just measure force—it quantifies function.

From Raw Numbers to Meaningful Metrics

The first step in making sense of the data is to look beyond a single, raw number and focus on key performance indicators (KPIs) that provide deeper context. Experienced professionals rarely fixate on one data point in isolation. Instead, they analyze a cluster of metrics to build a complete picture of an individual's neuromuscular capacity.

These crucial metrics often include:

- Peak Force: This is the highest force generated during a contraction, typically measured in Newtons or pounds. It is the simplest metric, representing the absolute maximal strength a muscle group can produce in that specific movement.

- Rate of Force Development (RFD): This metric measures how quickly an individual can produce force. A high RFD is essential for explosive movements like sprinting or jumping, where force must be applied in a fraction of a second.

- Limb Symmetry Index (LSI): This is a comparative score, expressed as a percentage, that highlights the strength balance between an injured and an uninjured limb. An LSI below 90% is a widely recognized indicator that an athlete may not be ready to return to sport after an injury such as an ACL tear (1).

Applying Data in a Clinical Scenario

Let's consider a real-world example. A physical therapist is working with an athlete six months after ACL reconstruction. The athlete reports feeling strong, but subjective feelings can be misleading. To make an evidence-based decision on their return-to-play status, the therapist uses a dynamometer to test the quadriceps strength of both legs.

The test reveals that while the athlete's peak force is improving, their injured leg still shows a Limb Symmetry Index of only 82%. More importantly, the Rate of Force Development on their surgical side is significantly lower than the uninjured side.

This data provides the therapist with several critical insights. The athlete has a clear strength deficit that places them at a higher risk of re-injury. The poor RFD also indicates a lack of explosive power, which is essential for safely cutting, jumping, and landing in their sport.

Armed with these objective numbers, the therapist can confidently determine the athlete is not ready for a full return to sport. More importantly, they can now design a highly targeted training phase focused on building explosive strength in the recovering limb. To see how these tests are performed step-by-step, you can review our guide on how to use a dynamometer. This is what a data-driven approach looks like—it replaces guesswork with precision, leading to safer and more effective rehabilitation.

Comparing Dynamometer Types in Sports and Rehab

Knowing how a dynamometer works is one thing, but selecting the appropriate one for a specific task is what truly matters. In the fields of sports and rehabilitation, the choice of tool depends on the question you are trying to answer.

Each type of dynamometer offers a unique window into muscle function. The decision often involves balancing portability, cost, and the level of detail required for the assessment, whether it's a quick strength check on the field or an in-depth analysis in a laboratory.

Handheld vs Isokinetic Dynamometers

Two of the most common tools in clinical practice are handheld dynamometers (HHDs) and isokinetic dynamometers. HHDs are small, portable devices ideal for quick, isometric strength tests. A therapist can easily carry one to assess a patient’s quadriceps strength on a treatment table or an athlete’s shoulder on the sidelines. They deliver fast, reliable data on peak force.

Isokinetic dynamometers, in contrast, are large, stationary machines typically found in research labs and high-performance centers. Often considered the "gold standard," these systems measure muscle strength at a constant, controlled speed throughout an entire range of motion. This provides a much richer picture of how a muscle produces force at different joint angles, offering deep insights into power and endurance that HHDs cannot match.

Think of it this way: an HHD provides a snapshot of maximal strength at one specific point. An isokinetic system provides the whole movie, showing how that strength changes dynamically through movement.

Force Plates: A Powerful Cousin

While not technically a dynamometer for measuring a single muscle, force plates are an important part of the strength assessment family and operate on very similar principles. Instead of isolating one muscle group, they measure the ground reaction forces an individual's entire body produces during movements like jumping, squatting, or landing.

Like dynamometers, force plates use highly sensitive sensors—often strain gauges or piezoelectric crystals—to convert mechanical force into precise digital data. They are indispensable for analyzing explosive power, balance, and landing mechanics.

If you wish to learn more, our guide on force plate testing is an excellent resource. Each of these tools, in its own way, helps answer the question "how strong is it?"—but tailored for a very specific context.

Comparing Common Dynamometer Types in Practice

Every clinician or coach must weigh the advantages and disadvantages of different tools based on their specific environment and goals. Here is a quick breakdown of how these common dynamometers compare in real-world applications.

| Dynamometer Type | Primary Use Case | Key Advantage | Limitation |

|---|---|---|---|

| Handheld (HHD) | Quick isometric strength tests (e.g., sideline, clinic) | Portability and ease of use | Limited to isometric tests; data can be influenced by tester's strength |

| Isokinetic | In-depth lab analysis of strength through a full range of motion | "Gold standard" accuracy and detailed dynamic data | Expensive, large, and not portable; requires a trained operator |

| Force Plate | Analyzing whole-body power and biomechanics (e.g., jumps, landings) | Measures ground reaction forces for functional movements | Does not isolate specific muscle strength; requires dedicated space |

Ultimately, the best device is the one that provides the most actionable information for your client or athlete. Whether it's a portable HHD for routine check-ins or a force plate for a full biomechanical workup, understanding the strengths of each is key to making an informed decision.

Common Misconceptions About Strength Testing

Dynamometers offer incredible insight into muscle function, but several common myths can complicate the interpretation of their data. Understanding how a dynamometer works is only half the battle; addressing these misconceptions is equally important for its effective use in clinical or high-performance settings.

One of the most significant misconceptions is that a higher number is always the goal. While peak force is a key metric, it rarely tells the whole story. Context is crucial. A high peak force reading has limited meaning if there is a significant strength imbalance, or limb asymmetry, between the left and right sides (1). Such imbalances are often considered a significant indicator of increased injury risk.

Not Just for Elite Athletes

Another common idea is that dynamometers are tools reserved for professional athletes in specialized performance labs. This is far from the truth. Their role in geriatric care and post-operative rehabilitation is, in many ways, just as critical.

Consider an older adult recovering from hip surgery. Objective strength data is vital for tracking their progress and ensuring they can safely perform daily activities. Similarly, for a patient recovering from a stroke, a dynamometer provides quantifiable feedback on their neuromuscular recovery that a subjective assessment cannot.

Complexity and Accessibility

Finally, there is a lingering perception that dynamometers are complex, research-grade instruments that are difficult to use. While this may have been true for older, lab-based systems, modern handheld dynamometers are designed to be user-friendly.

Today's devices, with their intuitive digital interfaces and straightforward testing protocols, make it easy for any practitioner to gather objective data quickly. This accessibility has been a major factor in bringing evidence-based strength measurement out of the laboratory and into everyday clinical practice.

Your Top Dynamometer Questions, Answered

To conclude, let's address some of the most common questions that arise when clinicians begin using dynamometers.

How Accurate Is a Handheld Dynamometer, Really?

This is an excellent question. Handheld dynamometers (HHDs) are known to be accurate and reliable, but with one major condition: the testing protocol must be highly standardized.

The precision of the measurement depends heavily on the tester's technique. It is essential to stabilize both the device and the person being tested. Consistent placement on the body is also non-negotiable for reliable results (1). When these factors are controlled, the data is robust.

A practical limitation can occur when testing a very strong muscle group, as the tester's own strength may be insufficient to provide a stable anchor. Despite this, numerous studies have demonstrated that HHDs compare favorably with "gold standard" isokinetic systems, making them valuable tools for clinical and field settings.

What’s the Difference Between Isometric and Isokinetic Testing?

This question addresses two fundamental ways of assessing strength.

-

Isometric testing measures static force. Imagine pushing against an immovable wall—the muscle contracts, but its length does not change. This test provides a snapshot of a muscle's peak force generation. It is a simple and direct measurement.

-

Isokinetic testing is dynamic. It measures muscle force through a full range of motion, but—and this is the key—at a constant, controlled speed. The machine's resistance adapts to the force produced by the individual to maintain that constant speed.

Therefore, an isometric test is the go-to for determining a muscle's absolute peak strength. If the goal is to see how that muscle functions and produces power throughout a movement, isokinetic testing is the appropriate choice.

Can a Dynamometer Be Used to Measure Fatigue?

Absolutely. In fact, it is one of the best objective tools available for this purpose.

A typical fatigue protocol involves having an individual perform a series of maximal contractions over a specific period. The focus is not just on the first repetition but on the performance over the entire set.

The dynamometer records the decline in force from the first repetition to the last. This allows for the calculation of a fatigue index, which is a powerful metric for understanding endurance, tracking recovery after an injury, or making informed decisions about an athlete's readiness to return to competition (1).

At Meloq, our goal is to provide professionals with precise, portable, and straightforward digital tools to move beyond subjective guesswork. Our ecosystem of devices, including the EasyForce digital dynamometer, is designed to deliver the objective data needed to make confident, evidence-based decisions for your patients and athletes.

See how our tools can elevate your practice by visiting us at meloqdevices.com.